Description

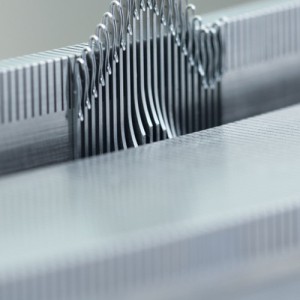

1. Needle models: 109/130 are our self-developed high-speed needles, which can increase the output of the machine and have superior performance.

2. Bump-free stitch gliding is very important for an aesthetically pleasing product and perfect fabric.

3. This is why the geometry and surface of the stitch gliding area of the needles are particularly important where it involves the continuous and precise production of knitted fabrics on large circular machines with ultra-fine gauges.

Benefits

Latch needles guarantee the best fabric quality, including in the finest knits. Productivity is effectively boosted with high speeds.

At the same time, latch needles can achieve energy savings which lower production costs.

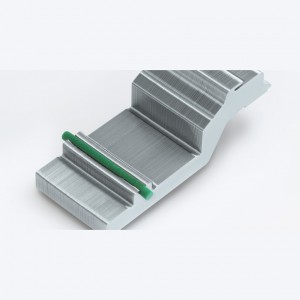

The tapered hook provides an enlarged cross-section at the bottom of the hook and tapers to the tip.

Reducing the width of the lock head also reduces the weight of the lock, thereby reducing wear and tear of the lock against the hooks in the lock seat and the lock impact on the lock.

By reducing wear on the ring-forming portion of the needle, the life of the needle can be significantly improved.

The tapered hook allows the needle to be designed with greater clearance between the needle and the sinker than is the case with conventional needles with cylindrical hooks.

This allows both fancy yarns and low-quality yarns with thick and knotted knots to be processed to optimum quality standards without problems.

For example, if you are knitting a yarn with obvious thick or large knots, it may happen that the hook is pulled up.

This in turn results in longitudinal streaks or double threads that can sometimes only be detected after the knitwear is finished.

Result

1. Reduce energy consumption, increase product reliability, make machine operation easier, and improve all subsequent processes.

2. Lower energy consumption and lower machine temperature are just two of the advantages offered by the needle series, designed for high performance circular knitting machines.

3. Uniform loops and perfect fabric quality

4. Demonstrable reduction in CO2 emissions.

5. The optimized needle shank geometry creates less friction in the machine, resulting in lower power consumption.