NPF241B(CICX)

Our feature:

1.The steel wire of NPF yarn storage wheel adopts special surface treatment technology, so that the yarn storage wheel has excellent anti-corrosion and anti-wear performance;

2.The yarn gripper has excellent craftsmanship and strong wear resistance;

3.The yarn knot filter is sturdy with screws, easy to replace, and adopts a rotary structure, which is easier to adjust;

4.Yarn clamping plate, yarn knot filter and yarn feeding porcelain ring are designed as a whole to ensure that the yarn number is in the middle of the yarn knot filter during yarn storage, preventing the yarn from cutting into the yarn knot filter;

5.It has the function of locking the front and rear probe rods, which is convenient for debugging or idling operation. It has anti-static function and does not accumulate static electricity.

Accessories information:

1.Optional drive pulley: A-type punching hole pulley B-type synchronous pulley yarn clamping method can be selected: spring clamping plate, magnetic clamping plate

2.Optional 1 to 3 layers of drive pulleys

3.Voltage Specifications: LED

ZPF20-B28(CICX)

Item NO.: Positive Feeder

Product Origin:jiangsu, China

Lead Time:3-7 working days

Warranty:1 year

Rated voltage (machine stoppage): 12V or 24V

Rated current: 60mA or 50mA

Minimum yarn tension: 1 cN (centiNewton)

Weight depending on model: 430g to 660g

Our feature:

1.The yarn storage wheel steel wire is made by a special process, so that the yarn storage wheel has excellent anti-corrosion and anti-wear properties;

2.It has the function of locking the front and rear probe rods, which is convenient for debugging or idling. Use a magnetic clamping plate, a spring clamping plate or an adjustable magnetic clamping plate (can be selected by the customer).

ZPF series features:

1.With bright surface treatment, easy to clean and maintain. The lightweight probe reduces the yarn feed tension.

2.Equipped with magnetic yarn clamping plate to eliminate the difference of yarn feeding tension adjustment.

Accessories information:

1.Optional drive pulley: A-type punching pulley B-type synchronous pulley.

2.Yarn clamping method can be selected: spring clamping plate, magnetic clamping plate or adjustable magnetic clamping plate.

3.Optional 1 to 3 layers of drive pulleys

4.According to the thickness of the yarn, the width of the clearer groove is 0.40mm, 0.5mm, 0.6mm, 0.8mm, 1.2mm, or it can be controlled by a rotary yarn clearer circuit. Optional: double-core circuit, single-core circuit Voltage specification: 12V/24V

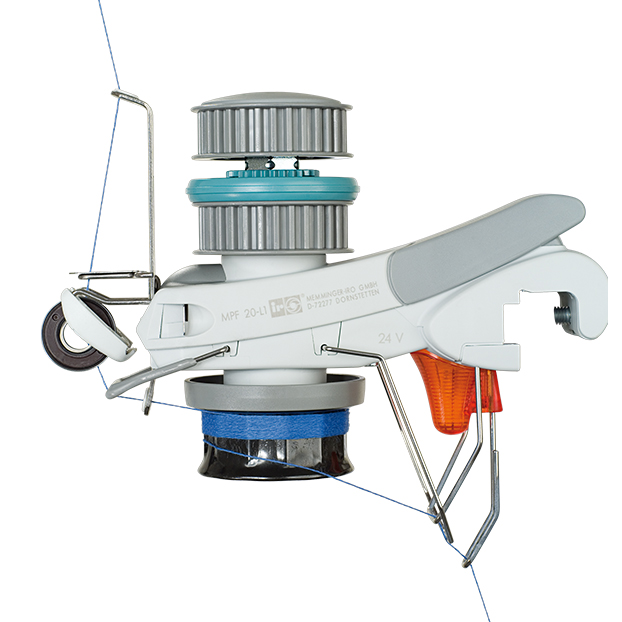

MPF P(MMG)

Item NO.: Positive Feeder

Product Origin:Zhejiang, China

Lead Time:3-7 working days

Warranty:1 year

Power supply: 12/24 V AC/DC, 50 - 60 Hz

Rated current: 60mA

Yarn tension range: 1,0 cN to 20 cN

Yarn gauge range:

Staple yarn: Nm 6 to Nm 200

Filament: 8 dtex to 2000 dtex

Elastomers: spun, wound

Weight depending on model: 430g to 660g

This device comes with the tried-and-tested, self-cleaning vibrating yarn tensioner, which reliably prevents machine stoppages. Fast threading saves time. The colour-change LED stop light is an integral part of the feeder body and is clearly visible from any operator position. The enclosed feeder body prevents contamination, contactless stop motion system for yarn breakage.

Main features

1.Self-cleaning vibrating yarn tensioner prevents machine stoppages

2.Rapid threading thanks to open eyelets

3.Interchangeable yarn feed wheel

4.Integrated anti-filamentation unit on yarn outlet

1. Vibration tension device

The vibrating design makes the tension disc rotate in the opposite direction of the yarn feeding of other competitors in the market, which can prevent the tension disc from accumulating fluff and has a self-cleaning effect. There is no problem of wear and tear of the tension disc, and there is no more false stoppage, which means that the weaving capacity is improved.

2. Yarn storage wheel

The full-cover type yarn storage wheel is standard equipment for yarn storage, and the needle bar fence type or separable yarn storage wheel is optional. Fully removable and replaceable.

3. Stop indicator light

A large stop indicator built into the feeder is clearly visible to all operators from all angles.

4. Built-in retractable anti-residual wire device

When using filament yarn, the capillary monofilament is easily entangled on the yarn storage wheel and hinders the smoothness of the yarn path. To avoid this situation, the operator can select the yarn guide bar at the flat yarn output angle of the spun yarn or the filament yarn. The steeper yarn exit angle.

5. Knot filter

No tools are required to change the knuckle filter - the adjustable multi-slot knuckle filter is available.

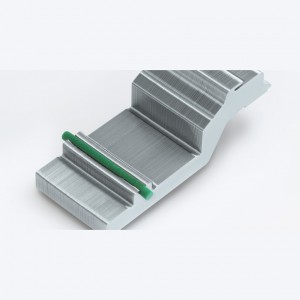

MPF L(MMG)

Item NO.: Positive Feeder

Product Origin:Zhejiang, China

Lead Time:3-7 working days

Warranty:1 year

Power supply: 12/24 V

Rated current: 60 mA or 50 mA

Min. yarn tension: 1 cN

Weight depending on version: 430 g to 660 g

Application

The MPF L impresses with its self-cleaning tension rings on the yarn infeed tensioner and closed, wear-free yarn feed wheel. Other features include the integrated anti-filamentation unit and accessible yarn outlet tension to approx. 1 cN.

Main features

Ease of operation, maintenance-friendly, wear-free and long service life, Self-cleaning vibrating yarn tensioner prevents machine stoppages and boosts productivity, Even tension force due to magnetic tension rings.

1. Vibration tension device

The vibrating tension disc rotates in the opposite direction to the incoming yarn. Effectively avoid the accumulation of dirt on the tension disc, which is called self-cleaning.

2. Closed storage feed rollers

This closed, wear-resistant yarn storage and feed roller prevents the accumulation of residual yarn when handling multifilament yarns.

3. Built-in anti-residue device

When processing multifilament yarns, capillary filaments can build up on the yarn storage rollers and prevent smooth yarn feeding. The user can choose to output the yarn at a flat and shallow angle when weaving short-fiber yarns and at a steeper angle when multi-filament filament yarns are used to avoid the accumulation of residual filaments.

4. Yarn feeding cantilever (optional)

This structure omits the yarn feeding guide arm installed on the upper edge of the yarn feeder, which makes it quicker and more convenient to replace the belt.