-

-

Terry Circular Knitting Machine For Towel Fabric

Leadsfon brand cost-effective terry machine, model JSP, It can knit plain, spandex fabric and can make a towel.

-

Single Jersey Circular Knitting Machine For Highly Productive

Leadsfon brand high speed single jersey circular knitting machine, model SJ3.0, It can knit plain, spandex, mesh fabric and can make sportswear, swimsuit and so on.

-

Three Thread Fleece Circular Knitting Machine For Good Quality

Three fleece thread machine is Italian design .The best choice for the market-tested three fleece thread machine. Three fleece thread machine have excellent interchangeability and Higher fabric quality. Our three fleece thread machine are good at cost – effective & after-sales service.

-

Sinkerless Singe Jersey Circular Knitting Machine For Latest

Leadsfon brand lastest sinker-less single jersey circular knitting machine, model SL3.0, can knit plain, spandex, mesh fabric and can make sportswear, swimsuit and so on.

-

Double Jersey Circular Knitting Machine For High-Performance Customized

Leadsfon brand high productive double jersey circular knitting machine, model DJC2.0/2.4, It can knit plain, interlock, spandex, mesh fabric and can make sportswear, swimsuit and so on.

-

Double Jersey Circular Knitting Machine For High Speed

Leadsfon brand high output double jersey circular knitting machine, model DJI3.2, It can knit plain, interlock, spandex, mesh fabric and can make sportswear, swimsuit and so on.

-

Double Jersey Rib Knitting Machine For High Production

Leadsfon brand high fabric quality rib machine, model DJR1.8, can knit rib fabric and can make the cuff, collar, vest and so on.

-

Yarn Feeder Spare Parts For Circular Knitting Machine

Rated voltage (machine stoppage): 12V or 24V

Rated current: 60mA or 50mA

Minimum yarn tension: 1 cN (centiNewton)

Weight depending on model: 430g to 660g -

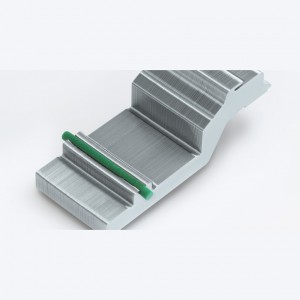

Take Down For Circular Knitting Machine

Single-sided machine: fastest (200㎜/revolution), slowest (12.5㎜/revolution)

Double-sided machine: fastest (109㎜/rev), slowest (7㎜/rev)

Roll diameter range: Maximum (290φ㎜) -

Sinker For Circular Knitting Machines

Description Polyester yarn cuts deep grooves in a very short time – this means frequent sinker changes! Therefore, the design of the sinker is crucial. 1.During the fabric knitting process, knitting sinker is one of the most important part of the circular knitting machine, it has been playing a crucial role. Outstanding quality of the sinker is the base for knitting high quality fabric 2.For abrasive yarns such as polyester semi-gloss or elastane, the partial hardening on the ... -